Anionic surface sizing agent is a new type od surface sizing agent that synthesized by the copolymerization of styrene and ester.It can efficiently combinate with starch result good cross link intensity and hydrophobic properties.With lower dosage,low cost and easy use advantages,it has good film-forming property which can significantly improve the water-resistance and ring-crush strength of writing and printing paper,such as offset printing paper and electro-photographic paper. Alkyl ketene dimer (AKD wax), Cationic Reagent (3-Chloro-2-hydroxypropyltrimethyl ammonium chloride/quat 188/CHPTAC), general AKD emulsifier 25%, Quat 188 69%,Polymer emulsifier 40%, PolyDADMAC 40%,Wet strenght agent 12.5%/25%, Styrene Acrylic Copolymer, Fixing agent 50%, Poly Aluminium Chloride, Sodium Gluconate Oxidized starch,ect.

Our quality can compete with BASF400DS and BASF8903.

| Item | Specification |

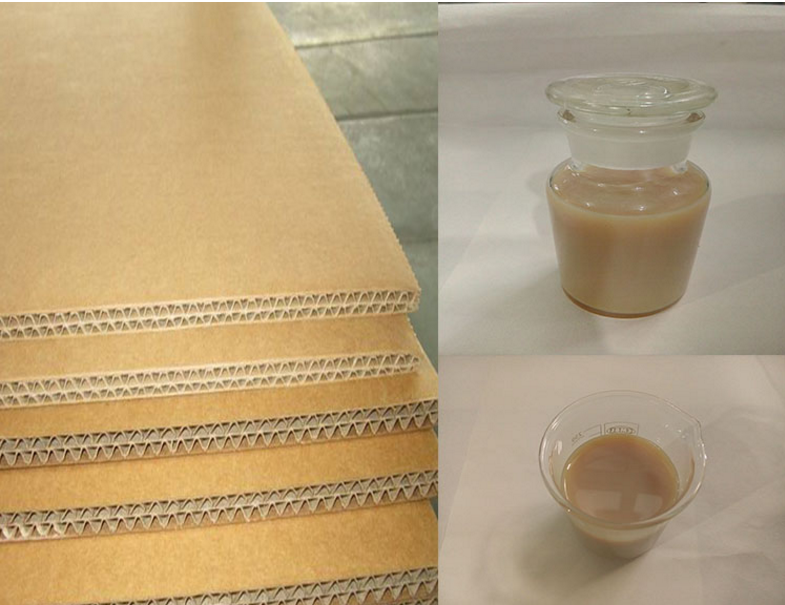

| Appearance | White to light brown liquid |

| Solid content | 25%min |

| PH | 2-4 |

| Viscosity(25℃).cps | 50max |

| Ionic charge | Anionic |

| Storage period | 6 months |

It can be applied in combination with anionic and nonionic auxiliaries such as starch,direct dyes,acid dyes and fluorescent whitening agents,etc.

The paper does not necessarily have to be sized at the wet end and before it is applied,but this can be an effective means of controlling the extent to which the size is able to penetrate.

It can significantly improve the water-resistance and ring-crush strength of offset printing paper and electro-phototgraphic paper.

It also has good mechanical stability with less bubbles generated during the operational process.

Application temperature should be below 75℃.

200kg PE drum or 1000kg IBC drum.