Tiancheng is one of the world`s largest manufacturers of Alkyl ketene dimer (AKD wax) with 20 years experiences and the largest and best manufacturer of Cationic Reagent (3-Chloro-2-hydroxypropyltrimethyl ammonium chloride/quat 188/CHPTAC), raw material for producing cationic starch in China. Other featured products:General AKD emulsifier 25%, Quat 188 69%,Polymer emulsifier 40%, PolyDADMAC 40%,Wet strenght agent 12.5%/25%, Styrene Acrylic Copolymer, Fixing agent 50%, Poly Aluminium Chloride, Sodium Gluconate Oxidized starch,ect.

1. Product name:

AKD High Polymer Emulsifier

2. Product introduction:

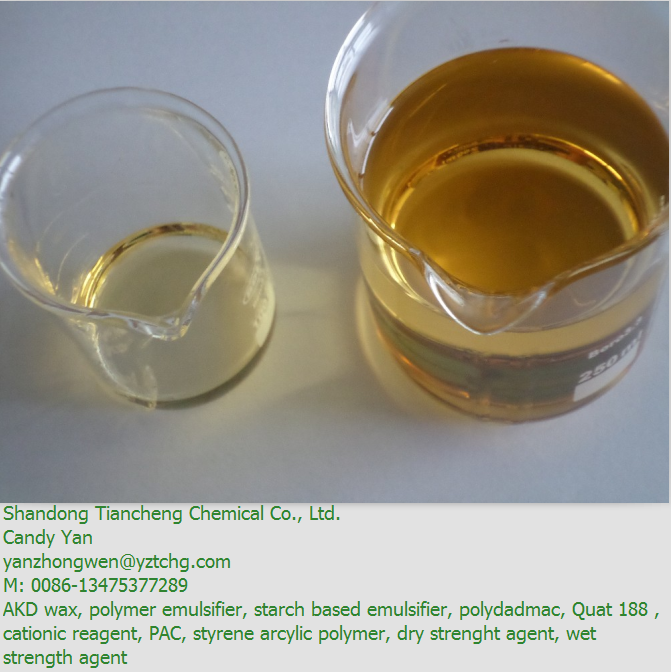

AKD high polymer emulsifier (instead of traditional cationic starch based) is a kind of cationic polymer product developed by our technical department,which is the initiative developed product in the market.It can not only emulsify AKD wax,but also proteched the AKD colloid dispersion and aid retention,it also can increase AKD sizing efficiency(2%-8%).It can get the high stability and better fixing effect AKD emulsion by mechanical stirring,in the meantime it greatly decrease AKD hygrolysis during storage and sizing process.Final AKD Emulsion shelf time is about 6 months which is longer than starch emulsified AKD emulsion.The final AKD Emulsion also has quicker curing effect.

3.Specification and Index:

| Item | Specification |

| Appearance | light yellow viscosity liquid |

| Solid content | 40%min |

| Viscosity,mPa.s,25°C | 2000-10000 mPa.s |

| pH value | 2-5 |

| shelf life | 6 months |

4. Application:

This Emulsifier greatly restricts the AKD hydrolysis and the migration aptitude.It can replace the starch based emulsifier and AKD curing agent,at the same time decrease the AKD WAX using quantity.The final AKD Emulsion by this high polymer emulsifier can realize 80% sizing effect after paper machine,and almost totally realize after rewinding,which can let the paper immediately get the good water resistance effect,so less surface sizing agent in size press can fulfill all the sizing requirement.For detail using method,please contact Greatland Chemicals Co.,Ltd.

5. Package and storage:

It should be stored in the warehouse with dry and cool condition protected from frozen and sunlight directly. The temperature should be below 30°C.

Packing with 200kg, 1000kg/drum.

Product Categories : Paper Making Auxiliary Series > High Polymer Emulsifier