Shandong Tiancheng Chemical Co.,Ltd is the lead manufacturer of Alkyl Ketene Dimer AKD Wax in China . Since 2008 , Tiancheng quality and quantity have been ranked top in the world, during we adopt the advanced production equipment and production technology , our quality is more and more best , the purity higher 90% . the output quantity reach more than 40000 ton per year .Alkyl Ketene Dimer(AKD WAX) which is made of high fatty acid (≥12) .This is acylated and dehydro chlorinated . This product as a kind of initial powder of neutral sizing agent, is used in making neutral sizing agent latex of paper pulp . After sizing with AKD emulsion, it can make paper less water absorbing and controls its printing properties. Our company produce a series of paper chemical including AKD emulsion , Surface sizing agent , Wet Strength Agent (PAE) ,Dry Strength Agent (PAM) , Retention aid ,Lubricant , Fixing Agent ,surface agent , Cationic Reagent (PTAC) ,polymer emulsifier , AKD Emulsifier , special strach for AKD , Zirconium Oxychloride , Dispersant , Curing Agent (polyDADMAC) ,Bactericide ,Defoamer,Water Repellent Agent, Wet strength release agent,Theology modifer,etc.

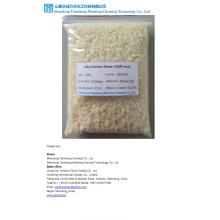

Specification:

(1).Appearance-----------------------------granular ivory-white, yellowish solid

purity------------------------------------------>90%

Melting point---------------------------------48-50C

FFA(free fatty acid)--------------------------<2.0

Weight loss-----------------------------------<1.5%

Acidity-------------------------------------------5%

Alky Length------------------------------------C16/C18

lodine value------------------------------------44-45

Packing------------------------------------------25kg/bag ,500kg per bag

Loding Capacity--------------------------------15.0MT/20FCL

Product Application

AKD wax can be made into AKD emulsion applied as in sizing agent in the papermaking production.

AKD wax is emulsified by the cationic emulsifier, and melted AKD wax and emulsifier undergo high-speed shearing and high pressure homogenization to form the liquid AKD sizing agent after cooled.

In the papermaking process, application of AKD sizing agent gives the fluid resistance to paper and paperboard to prevent or delay the penetration and diffusion of some liquids on paper fibers, thus satisfying people's requirements on the processing and use of paper products.

Product Advantages

1. Technical Ability

Tiancheng Chemical is one of the drafters for National Standard on AKD wax. With a twenty-year history of production of AKD wax, it has been devoting to the quality improvement and R&D. We are not only the manufacturer of AKD wax, but the user. This helps us to deeply analyze AKD wax, and to mature and stabilize the production technology of AKD wax. Tiancheng Chemical continuously extends its AKD wax industrial chain to the front end from AKD wax to chloride to phosgene, in order to realize the integrative production mode.

2. Production Technology

Tiancheng Chemical adopts the solvent techniques for production, and products react fully with high conversion rate, and the product purity is higher than 90%, so that the multimer impurities can be reduced to the maximum degree. AKD sizing agent has high active Produced

by AKD wax can has high active contents and good emulsification effect.

In papermaking process, the sizing agent produced by Tiancheng AKD wax has the following advantages:

1) Low consumption per ton of paper, few hydrolysates generated, which has a small influence on the

permeability of paper-making molding net and dehydration in wet end of paper;

2) Wet-end formed paper has good water resistance, which can reduce paper breaking in the pressing and drying process of the paper machine;

3) Reduce the possibility of wax points on paper, reduce paper sliding cylinder and roller sticking to guarantee the normal running of the paper machine.

4) Effectively prevent sizing reversal and false sizing phenomenon.

3. Production Equipment

The production process of Tiancheng AKD wax adopts DCS automatic control; Adopt imported equipment, such as French De Dietrich reaction kettle, German SIHI vacuum pump, Kroll injector, E+H flow meter and control valve; Adopt the fully automatic packaging lines and pile up by the robot.

4. Quality Management

Tiancheng Chemical builds the perfect quality management system, based on which product

analysis detection and quality control are carried out by professional personnel; Own six sets of

U.S. Agilent gaschromatograph, two sets of Swiss Metrohm automatic potentiometric titration,

Japanese SHIMADZU liquid chromatograph, particle size detector, etc., strictly control raw

materials and product quality.

5. After-sales service

After-sales service team of Tiancheng Chemical has rich experience in production and application of AKD wax and AKD sizing agent, and serves to the papermaking industry for many years. The team not only solves production problems of AKD sizing agent for customers, but provides application technical support for customers to eliminate customers' worries.

Product Categories : Paper Making Auxiliary Series > AKD Wax